Common Trailer Issues That Require Immediate Service

When it comes to trailer trucks, even the smallest issue can quickly turn into a big problem if you leave it unchecked. Regular use, long hauls, and exposure to the elements mean wear and tear is inevitable.

Ignoring these signs can compromise safety, performance, and even lead to costly repairs in the long run. Identifying common issues early and knowing when to seek professional service are key to keeping your trailer in top condition and ensuring smooth operations on the road.

Brake System Failures

Trailer brakes are absolutely essential for safe stopping, especially when hauling heavy loads. A properly functioning brake system ensures that the trailer helps share the load when braking, rather than relying entirely on the tow vehicle. Without dependable brakes, not only is your stopping distance significantly increased, but the safety of your tow vehicle, trailer, cargo, and others on the road can all be at risk.

Signs of Failure

Weak or No Braking Power

If you notice that your tow vehicle is doing all the work when stopping and the trailer doesn’t seem to pull its weight, that’s a red flag. This could mean the trailer’s brakes aren’t engaging properly, leaving the towing vehicle to handle the entire braking force. That can quickly turn into a dangerous scenario, especially with heavy loads.

Grinding or Squealing Noises

Any unusual noises, like grinding or high-pitched squeals, are typically a sign of worn brake shoes or pads. They could also indicate that debris has entered the brake drum or caliper, causing unnecessary friction. Ignoring these sounds can lead to further damage and reduced braking performance.

Brakes Locking Up or Dragging

If the trailer brakes tend to lock up or drag excessively, you’re not just risking extra wear on your tires, but you’re also overheating the brakes. When this happens, it may pull your rig to one side during braking, which can be a serious hazard on the road.

Tire and Wheel Problems

Tires are the only part of your vehicle that actually touch the road, meaning their condition dictates not only your rig's performance but also your safety. Even the most robust braking system or advanced towing setup won't matter if your tires fail. Keeping them in optimal condition is non-negotiable—your tires are your lifeline on the highway.

Signs of Failure

Visible Tire Damage

Regularly inspect your tires for any deep cuts, cracks, or bulges in the sidewall. These can indicate structural weaknesses. Additionally, look for exposed belts or threads, which are clear signs that your tires are at the end of their lifespan and could fail at any moment.

Excessive or Uneven Wear

Uneven tire wear often signals deeper problems like poor alignment, faulty suspension, or improperly inflated tires. Don’t forget to check for tread depth inconsistencies. If one side of the tread is wearing faster, it could mean alignment or axle issues, while excessively worn centers or edges suggest inflation problems. A tire pressure monitoring system (TPMS) can help, but don't solely rely on it. Manually checking tire pressure periodically ensures accuracy.

Loose or Damaged Lug Nuts

If you hear a rattling, clunking, or any unusual noise from the wheel area while driving, stop to inspect it immediately. Lug nuts that have loosened over time, or ones that are stripped or damaged, can result in your wheel detaching entirely. Tightening and torquing lug nuts properly should be a regular part of maintenance before any trip.

Electrical System Malfunctions

A properly functioning electrical system is not only a legal necessity but a critical component of safe driving. Lights on your trailer communicate your intentions to other drivers. If your electrical system isn’t working correctly, you’re sending mixed signals—or no signals at all—which can have dangerous consequences.

Signs of Failure

Non-Functional Lights

If your brake lights, turn signals, or running lights suddenly stop working, the issue might be as simple as a burned-out bulb. However, more often, it could indicate a deeper problem, such as a wiring short or poor connection somewhere along the electrical path. Regularly inspecting and testing your trailer lights before long trips can help catch these issues early.

Flickering or Dim Lights

Flickering lights are usually a sign of a loose connection or a short circuit in your wiring harness. Inspect your connections, particularly around areas prone to corrosion or wear. If flickering persists, consider getting a professional inspection to uncover the root of the problem.

Blown Fuses in the Tow Vehicle

Repeatedly blowing fuses is a red flag. This often signals a more severe issue, such as a persistent short circuit in the trailer wiring. The only way to address this is to trace and repair the faulty wire. Ignoring it can leave you in the dark—literally—and potentially lead to more costly repairs down the line.

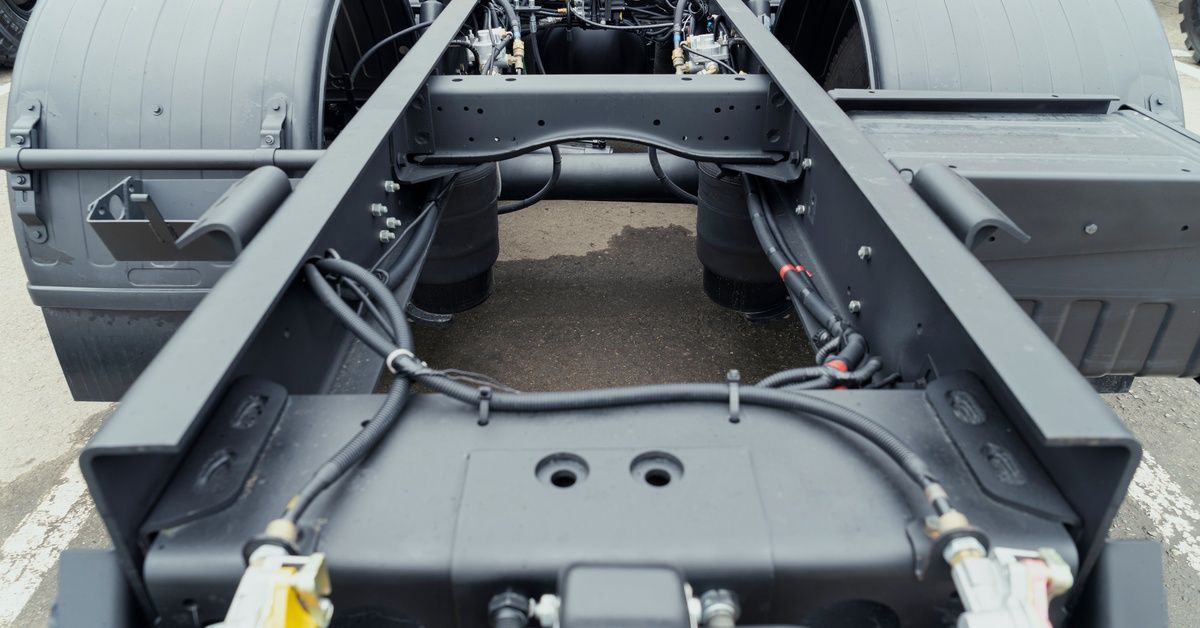

Structural and Frame Damage

The frame acts as the backbone, supporting the entire load of the trailer. It works in tandem with the suspension to evenly distribute weight, and the coupler keeps the trailer securely connected to the tow vehicle. Together, these parts ensure the trailer handles smoothly, even under heavy loads. If any of these components fail, the consequences could be disastrous, potentially leading to accidents, damage to your equipment, and harm to other drivers.

Signs of Failure

Cracked Welds or Bent Frame Members

Check the frame and tongue regularly for cracks, rust, or bent beams. Rust often weakens metal over time, and once you spot cracks or deformations, it’s a sign that the structural integrity has been severely compromised. These issues can worsen rapidly, so they need to be addressed as soon as possible.

Coupler Issues

Your coupler is what keeps the trailer connected. If you notice difficulty latching, excessive play once it’s attached to the hitch ball, or visible damage to the latching mechanism, it’s time for service. A poorly functioning coupler increases the risk of the trailer detaching while driving—a scenario that no one wants to face.

Broken Suspension Components

Damaged leaf springs, shackles, or torsion axles often lead to uneven trailer height or sagging. This not only affects how the trailer rides but also places undue stress on the frame and other components, potentially causing further damage down the line. You might also notice unusual swaying or bouncing as a sign of trouble.

At Trailer Tech, we understand that maintaining your trailer is critical for your safety and the safety of others on the road. By keeping these common issues in mind, you can service your trailers as fast as possible, so they continue to remain reliable and road-ready.

Whether it’s frame inspections, suspension work, or tackling other semi-trailer repairs, addressing problems early is always the smart move. Our expert team is here to provide top-tier repair and maintenance services so that you can have peace of mind every mile. Visit us today and find out how we can help keep your trailer in peak condition.